Introduction

Tri-gear Flowmeters are precise, reliable and rugged instruments for the volumetric flow of liquids in general industrial, petroleum and chemical applications that require high degrees of accuracy and repeatability. They operate on the Positive Displacement principle using advanced gear technology and offer a competitive alternative to their Oval Gear, Sliding Vane and Bi-Rotor alternatives.

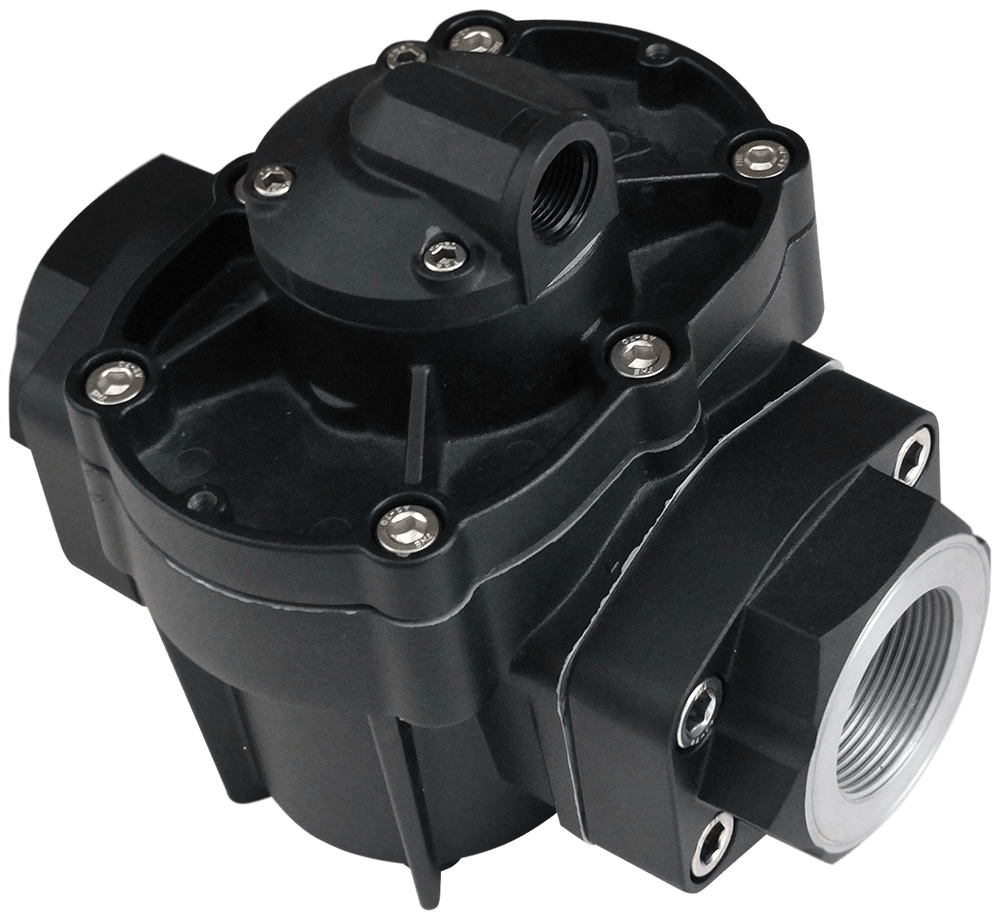

Principle of Operation

Liquid Passes into the single case measuring chamber and displaces two Tri-gears. Each rotation of a Tri-gear is proportional to a discrete unit of volume, in turn, the speed at which the gears rotate is directly proportional to flowrate. Reed and Hall Effect sensors mounted outside the pressure boundary detect the movement of the Tri-gears, thus allowing local or remote instruments to display flow total, rate of flow or facilitate batching applications.

Meters can be fitted with additional sensors to provide in phase or out of phase signals for applications such as bi-directional flow. The Tri-Gear based flowmeter outperforms its competitors when it comes to the accurate metering of the majority of clean liquids including Solvents, Alcohols, Fuels, Oils, additives, chemicals, food bases, paints and viscous emulsions whether pumped or gravity fed. Additionally it is an excellent, higher accuracy replacement for transmitting variable area (Rotameter) flowmeters.

Trigear flowmeter benefits:

High Resolution Digital Output

Wide Rangeability

Bi-directional flow capability

Digital or Analogue Outputs available

HART Output option

Less slippage than oval gear meters

Smoother and quieter than Oval Gear Meters

Dual Output standard (reed and hall effect)

Low Mass Tri-gears facilitate fast response time to step changes in flowrate